Automatic HTOL RF Test Systems

High Temperature Operating Life - Systems for Lifetime Prediction of Electronic Components

Becker Nachrichtentechnik offers industry leading turnkey solutions for fully automatic reliability testing, also called HTOL RF testing. The integrated test racks run complete test cycles using multiple RF frequencies without operator intervention. Becker Nachrichtentechnik prides itself for a high-quality modular design concept that also allows to customize the HTOL RF test systems according to specific customer requirements and scales from few to more than 200 channels. All devices under test (DUTs) are exposed to a high-power, individually controlled, precise RF signal.

Deploying Becker Nachrichtentechnik TSQA test systems in the reliability laboratory:

- Reduces R&D and operator effort running the test

An integrated webserver allows the configuration and control of the system without any software development effort at the customer side. Continuous automated monitoring of DUTs avoid interrupting the test period for intermittent health checks. The status of the test can be monitored from a remote office without entering the laboratory. The test cycle takes care of typical issues like e.g. DUT self-warming and switching off the stress in case DUT failure fully automatically.

- Delivers statistical data of better quality and higher quantity

Information about the DUT status is collected at operator defined intervals, so that analysis after the test can find early indicators of failure and exact failure time. Full closed loop-control of the stress level applied to the DUT removes any influence of failing DUTs to healthy DUTs (high isolation), as well as removing effects of temperature drift.

- Simplifies maintenance and debugging of cables and connectors

Typical problems in HTOL RF setups with large number of DUTs are related to wear or erroneous application of the cables and connectors. The graphical user interface allows to analyze the overall condition of the system and identify quickly bad cables or missing connections. The test will continue running correctly even if network connection or control PC is removed. The test results can be retrieved at some later stage, when connection and control PC is reestablished. The system includes a regular self-integrity check to alert the operator of any irregularity/ guarantee.

HTOL tests (High Temperature Operating Life) are an important element of reliability testing of microelectronic components like surface acoustic wave filter (SAW, BAW, FBAR, XBAR), low-temperature cofired ceramics filters (LTCC). Other target DUTs (devices under test) are diplexers, quadplexers and even complete front-end components (RFFE). These tests subject large batches of DUTs to RF stress at absolute maximum ratings and additionally to a high temperature of typically 125° C. The RF stress signals must be very precise and long term stable (1000 h and more) in order to create reliable statistics of the components’ life time. Devices under test that die from the stress during the HTOL test must not have any influence to neighboring devices in the same test setup. Test systems from Becker Nachrichtentechnik GmbH have been designed specifically for this application and guarantee high isolation between stress signals and highly precise output levels with no overshoot.

Fully Automatic 80 Channel HTOL RF Test System

guided webinterface Automatic Level Control (ALC)

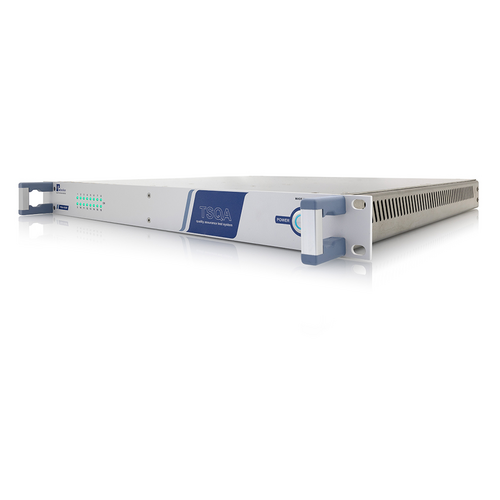

16 Channel, Precise High Dynamic HTOL RF System, 300 … 8500 MHz

guided webinterface Automatic Level Control (ALC) 300 ... 8500 MHz

Fully Automatic 8 Channel HTOL RF Sub System

guided webinterface Automatic Level Control (ALC)

Fully Automatic 8 Channel HTOL RF Sub System

guided webinterface Automatic Level Control (ALC)

Fully Automatic 80 Channel HTOL RF Test System

guided webinterface Automatic Level Control (ALC)

letzte Änderung: 03.09.2024